TEST PRINCIPLE

Comparison of the hardness of two soap formulations by penetration.

BACKGROUND

The penetration test is an Empherical test for the ease of penetration of soap. Results are influenced by product formulation.

METHOD

Equipment:

| Instruments: |

CTX with 50 Kg Loadcell |

| Probe: |

TA- 39 - 2 mm Cylinder Probe |

| Accessory: |

TA-CJ - Confectionary Jig, TA-BT-KIT- Fixture Base Table |

Settings:

| Test Type: |

Measure force in Compression |

| Pre-Test Speed: |

1.0 mm/s |

| Test Speed: |

2.0 mm/s |

| Post-Test Speed: |

10.0 mm/s |

| Target Type: |

Distance |

| Target Value: |

8 mm |

| Trigger Force: |

30 g |

SAMPLE PREPARATION

Remove the samples from storage and allow the samples to equilibrate to the testing temperature (room temperature in this case).

PROCEDURE

- Attach the 2 mm cylindrical probe onto the instrument

- Place the fixture base table onto the base of the instrument and loosely tighten with the thumb screws to enable some degree of mobility

- Place the confectionary jig onto the fixture base table and tighten into position using the side screws.

- Align the aperture of the confectionary jig to the probe above by repositioning the base table and ensure that the probe can penetrate the aperture of the confectionary jig without friction effects with the sides of the jig.

- Once the alignment is complete, tighten the thumb nuts of the fixture base table.

- Put the sample into the confectionary jig such that it is centrally aligned to the aperture of the fixture then tighten into position using the four screws. Tightening should be to the point of first resistance from the sample. Any further tightening will compress the sample.

- Lower the probe to about 5 mm above the confectionary jig.

- Start the penetration test.

- After each test, clean the cylinder probe before proceeding to the next test.

RESULTS

If the chosen bar soap is curved, use a sharp blade (knife) to flatten the testing surface if necessary. For comparison purposes, samples should be placed into the confectionary jig in the same orientation. The firmest sample is better tested first in order to anticipate the maximum testing range required for subsequent samples. This will ensure that the force capacity covers the range for other future samples. The penetration distance can be modified; however, the target distance chosen should be such that the probe does not touch the base of the container otherwise the instrument will be overloaded. In addition, resulting hardness values will increase relative to the increased penetration depths. Consequently, for comparison purposes, penetration distances must always be reported. The penetration test can also monitor hardness over temperatures that the soap may be subjected to during transportation and storage. Test temperatures must therefore be reported in the results. The soap penetration test can also indicate whether there are trapped air bubbles or a grainy texture seen as fluctuations in force as the probe comes into contact with air bubbles or hard particles.

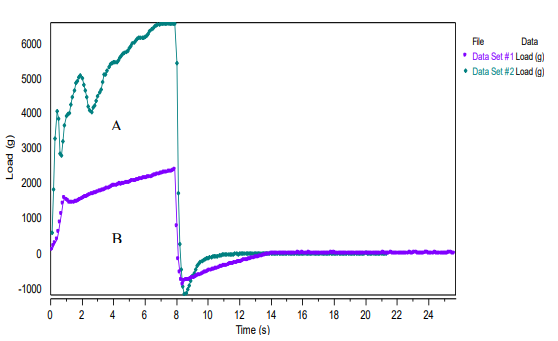

Figure I

Figure I A graph comparing the hardness of two different bar soap formulations tested at 20 oC.

Data Set # 1: Sample A (Premium Soap)

Data Set # 2: Sample B (Budget Soap)

OBSERVATIONS

When a trigger force of 10 g is achieved, the probe begins to penetrate the sample to a defined distance (e.g., 8 mm) at a set speed of 2mm/s. The highest peak value then becomes the force required to penetrate the sample to the specified distance. The higher the peak force value, the harder the sample. From Figure 1, Sample A is significantly harder than Sample B. The area under the graphs is a measure of the work done to penetrate the samples. This is the energy required to overcome the strength of the internal bonds within the sample. The table below shows the results for the tests obtained from 6 bar soap samples from each formulation to give the following mean peak fore and work done values below:

| Sample |

Hardness (g) |

Hardness Work Done |

| Sample A (Premium Soap) |

6087 ± 387 |

346.1 ± 59.8 |

| Sample B (Budget Soap) |

2421 ± 65 |

146.4 ± 5.5 |

>>Download a PDF of this application.